I use Solidworks for 3d printing functional prototypes for Industrial Design. 3d printing has quickly become the norm for prototyping quick parts and prices have fallen dramatically to 3d print parts. Even software such as solidworks, 3ds max, sketchup, rhino and more are now available to anyone because the software has become so intuitive that anyone can learn it without having to be an engineer, industrial designer, architect or in a similar field. Remember when making a photo realistic change in photoshop was magic? Now everyone knows a little something about it, has the software or a similar kind and can tweak their photos without thinking about it. Will 3d printing become that way for us? My personal opinion is no. Below are some thoughts I have about 3d printing, solidworks software, keyshot rendering and the projection I see Industrial Design taking in the years to come.

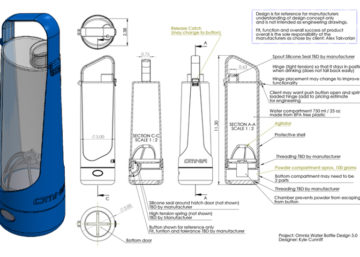

First lets talk about usability or practicality of 3d printing. Here at design sharpener we can take our designs from a very early stage and 3d print them for a client to test out for instance, the grip on a pan handle. Now in the “old” days as a designer right out of school from Pratt Institute I would literally carve foam with all sorts of tools (hot wire, knives, rasps, sandpaper) and use paper guides to get the foam model as close as possible to the design drawings. Now, all we have to do is click print. The difference though is that a foam handle is relatively easy to sculpt where as a print can take a week or more to have in hand. If a client wants to get the ball rolling fast, that could be a problem right?

Okay so a lot of clients ask before we a design sharpener get going on a project what they can expect to pay for a prototype or 3d print. The honest answer is that until I get going on the design and see what it looks like I won’t be able to tell. 3d printing costs are calculated by size, complexity (all those handsome little textures all over your design take time to print) and material, which I will cover below a bit. 3d printing costs are generally much lower than they have been but they can still be high, also because of print resolution and how you need to use your print. Does the 3d print need to feel like the real thing? Does the prototype need to act like the real thing? Does the prototype need to look like the real thing? These are all additional considerations for your prototype, costs and what you should expect to think about when considering a 3d print for your project.

There are so many options for 3d printing let alone pricing changes that its hard to predict. And without a solidworks 3d model to upload, your out of luck predicting. The thing to remember though, is that no matter how expensive a 3d print can be it pails in comparison to paying for a mold to manufacture your product for real. So its far wiser to test and possibly re-test your idea so you know its viable before going all out and paying for injection molding for instance.

3d print material can now be made of aluminum, steel, gold, all kinds of plastic that can flex, plastic that is translucent, plastic that is colored in different areas. Just about anything you can think of its there. The one material that continues to evade 3d printing, at least for now is silicone. This is a difficult material to print and while their are somewhat flexible choices out their nothing compares really to the real thing. So for now if your product is silicone (like a dog toy for instance) your stuck casting your idea the “old” way by hand to get a functional and feel right prototype.

3d Print complexity is also a major factor in predicting cost and if its the right way to have your prototype made. For instance, if their are a number of parts and they are heavily dependent on each other fitting right it important to remember 3d printing has larger tolerance requirements (depends on the material too) than a final injection molded plastic would be. 3d printing is not as precise and that is a limitation to might mean you should have a machine shop make your parts or maybe you don’t require such precision? It all comes down to your needs. Its important to understand 3d printing and its limitations before having your part made by a industrial designer.

Software is available for free like sketchup to model your idea. If you aren’t willing to learn a program and spend the untold hours learning how to use it finding an industrial designer will take care of that in a snap. Industrial designers are trained to take your napkin sketch idea and turn it into something that can be made while all along managing your expectations and guiding your design in the direction of a successful product that is economical to produce and that looks unique. Sometimes a clients attachment to that extra doodad on a idea of theirs needs to be changed to be made. Its a hard job but someone has to do it.

All in all I don’t see 3d printers being in every house-hold like a star trek episode. Between the cost, the practicality, accessibility, material, print quality, the print finish and appearance, I’d say its got a long way to go. But for now, it proves a valuable tool in a industrial designers tool box that can help a client see what their idea looks like in 3d, test out functionality and understand its viability before shelling out the big bucks for the final product. Its got pro’s and its got con’s. I can’t wait to see what the future will bring.