Portfolio

Click A Project Image Below For More Info

UrnForgettable Dog Urn Fire Hydrant

UrnForgettable Dog Urn Fire Hydrant3d PRINTING PROTOTYPES

Rogue Wave Toy Product Development

Rogue Wave Toy Product DevelopmentPRODUCT DEVELOPMENT

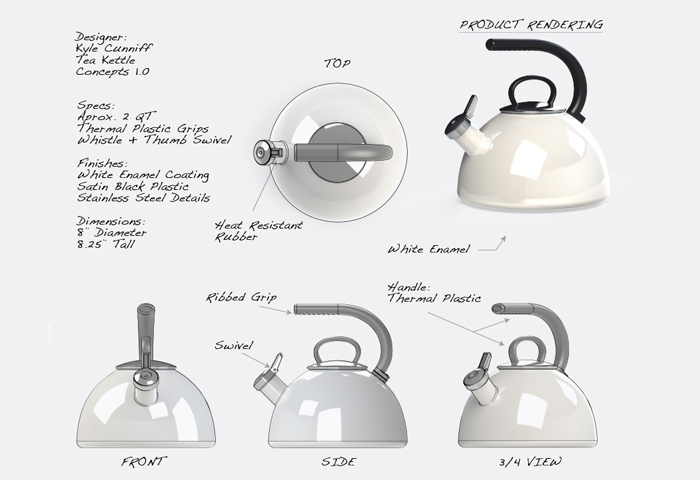

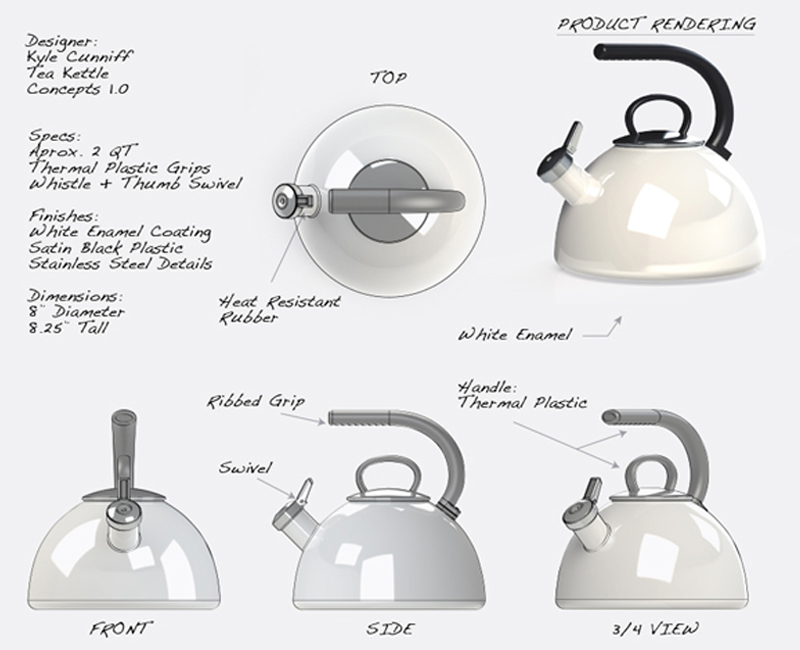

- Typical Design Project Concept Page ExampleJanuary 2, 2021

Typical Design Project Concept Page Example

Typical Design Project Concept Page ExampleConcept Development

Teether Toys for Skip*Hop’s Tree Top Play Things

Teether Toys for Skip*Hop’s Tree Top Play Things3D MODELING

Wave Physical Therapy Tool

Wave Physical Therapy ToolSURFACE MODELING

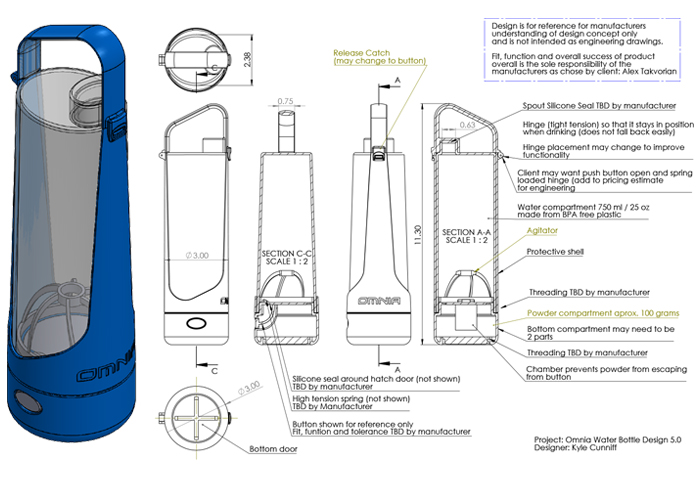

Eco Vessel Water Bottle Design

Eco Vessel Water Bottle DesignPRODUCT DEVELOPMENT

Zootensils Skip*Hop

Zootensils Skip*HopMANUFACTURING

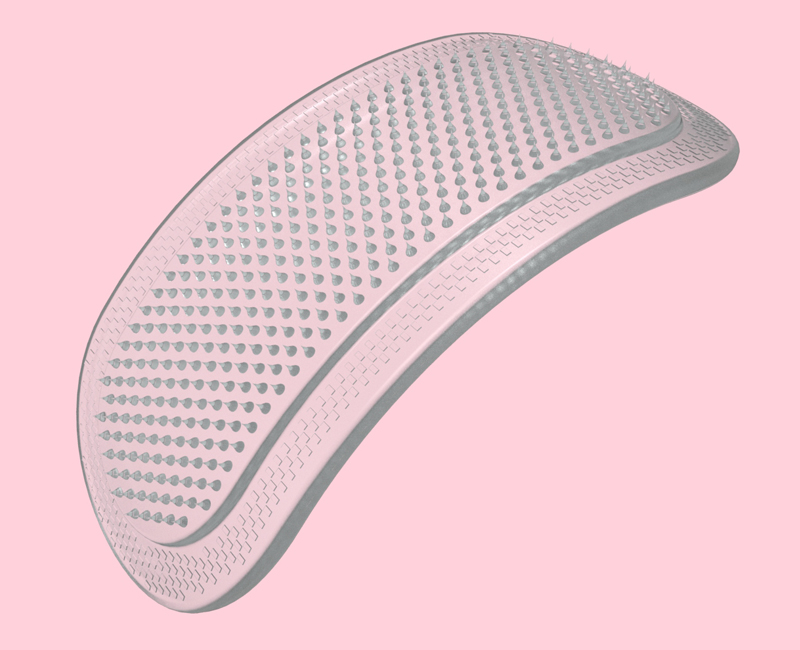

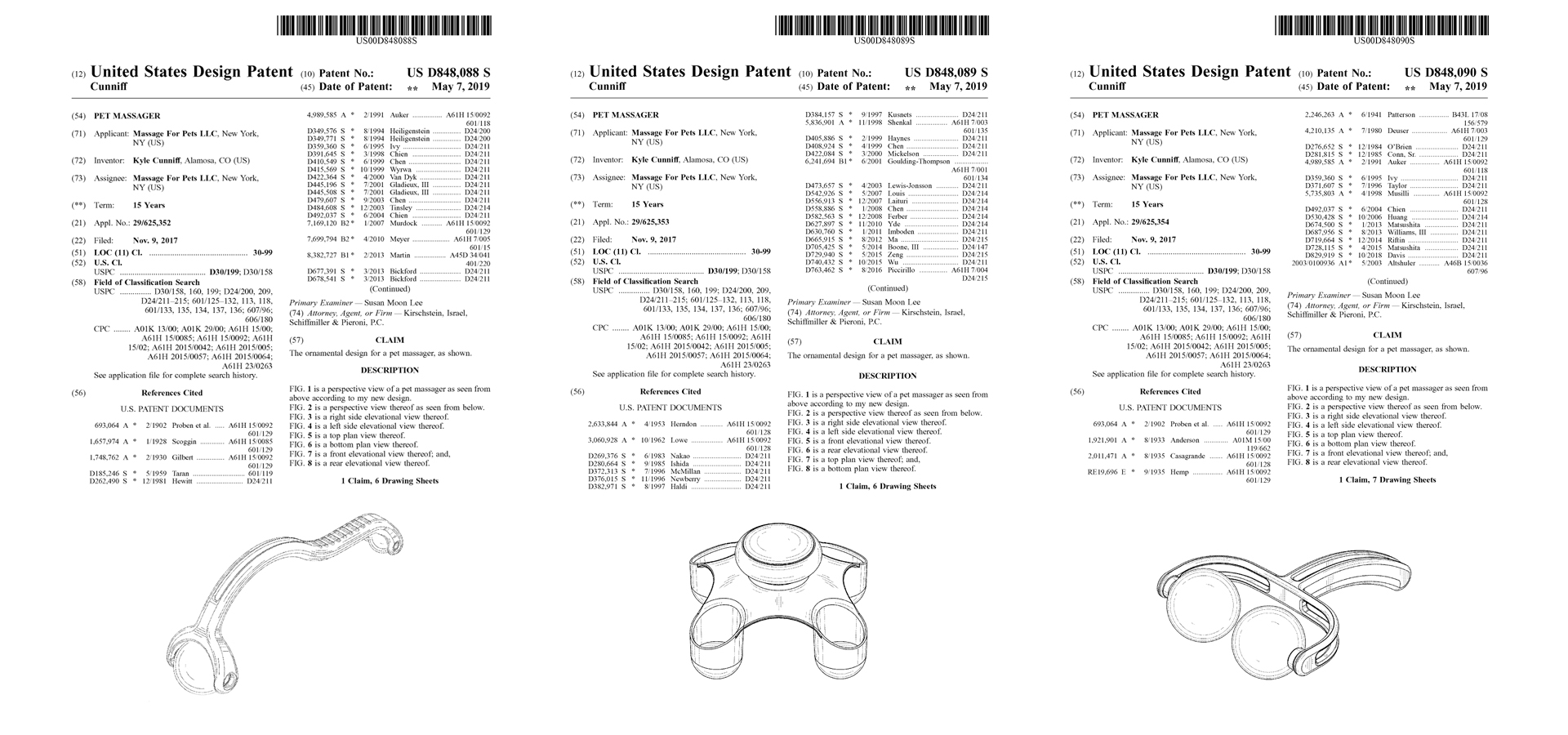

Petwell Pet Massage Products

Petwell Pet Massage ProductsMANUFACTURING

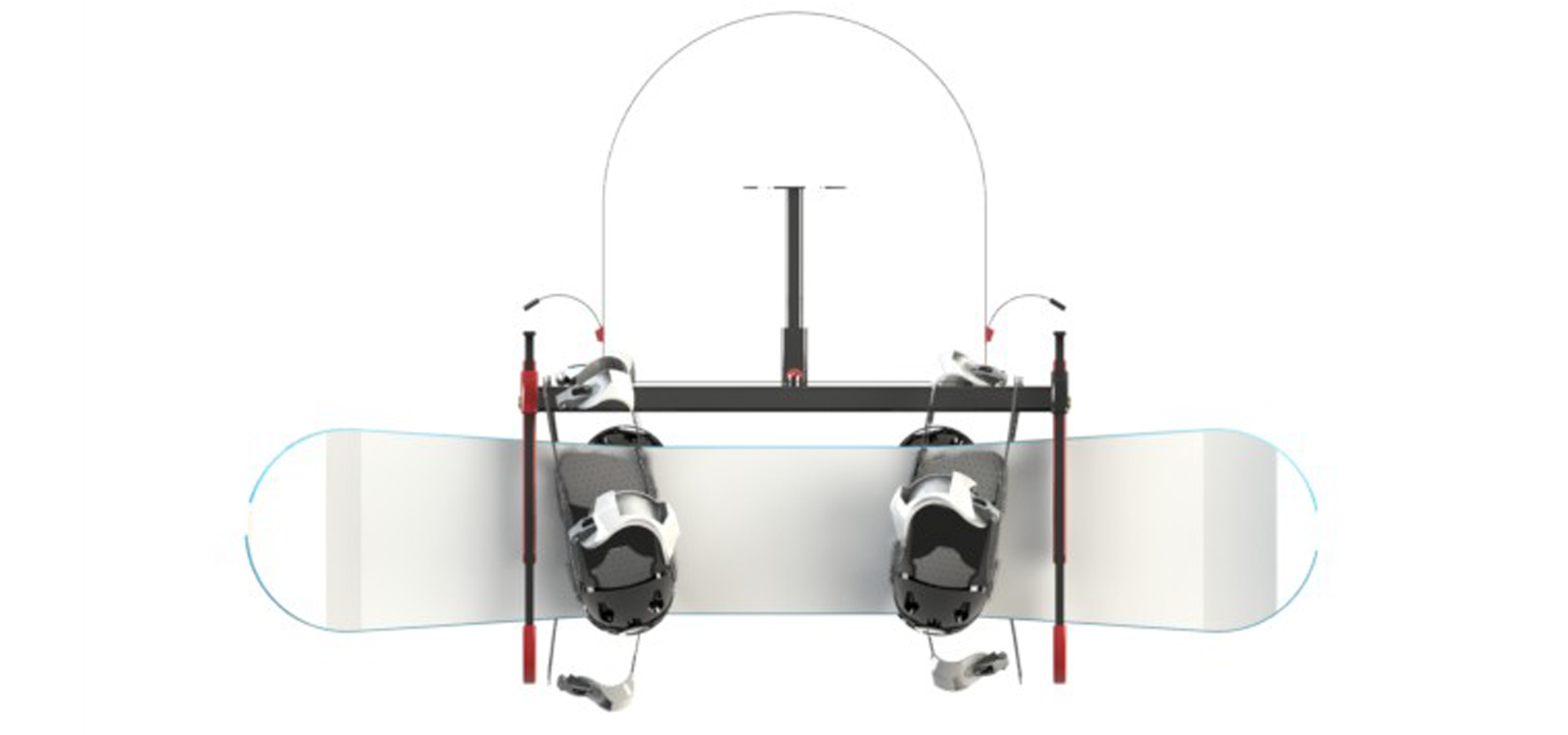

Jeep Wrangler Snow Board Rack

Jeep Wrangler Snow Board RackCONCEPT DEVELOPMENT

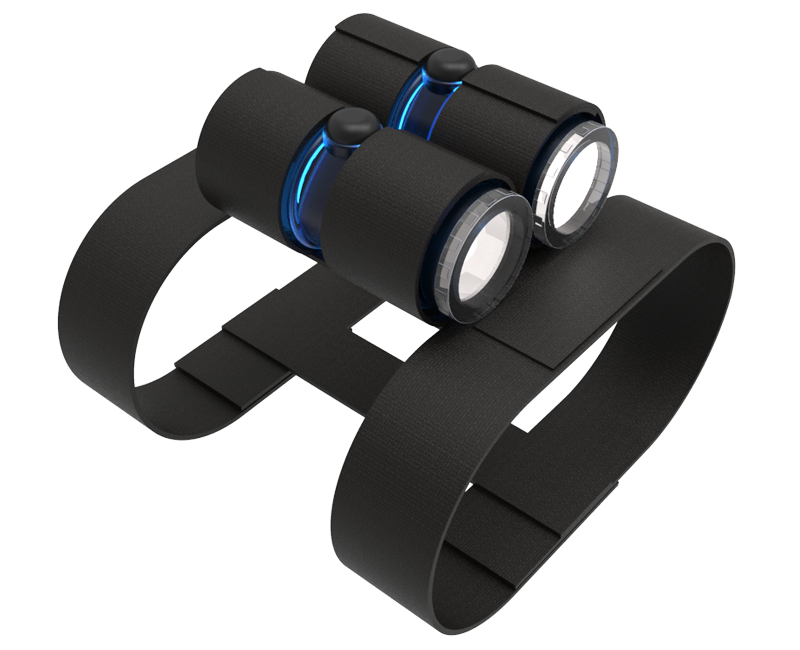

OLO Sanitizer Wrist Band

OLO Sanitizer Wrist BandINDUSTRIAL DESIGN

IBEX 30oz Tumbler Design

IBEX 30oz Tumbler DesignPATENT DRAWINGS AND MANUFACTURING

Peace Out Skin Care

Peace Out Skin CareProduct Rendering

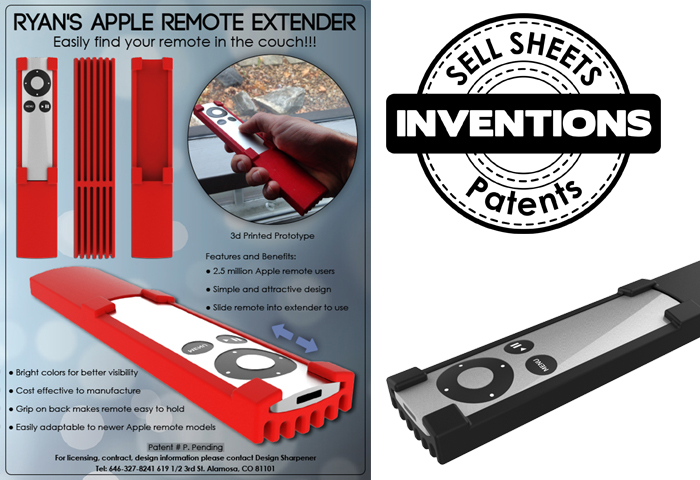

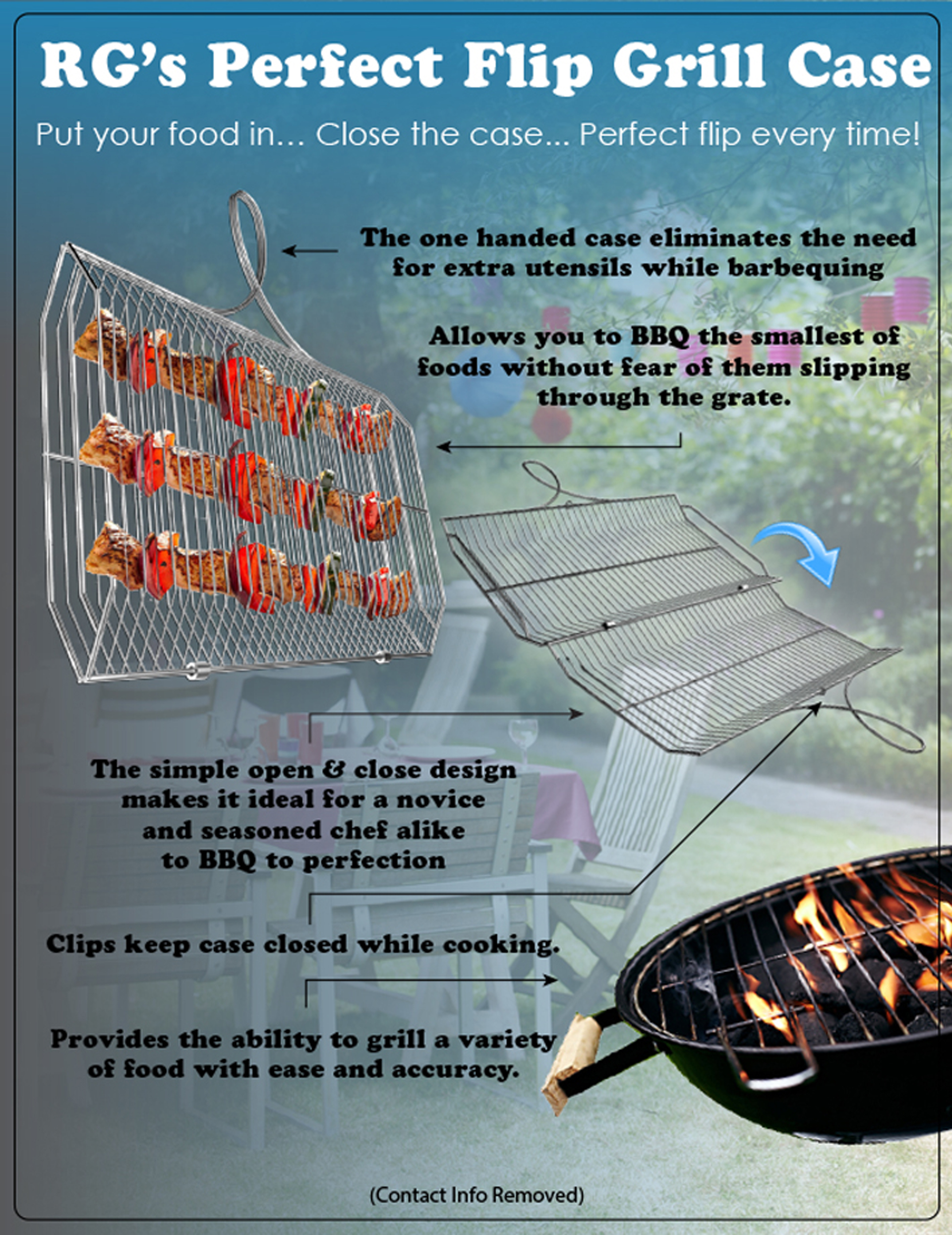

Invention Sell Sheets

Invention Sell SheetsLICENSE YOUR IDEA

Bee True Honey Company Packaging

Bee True Honey Company PackagingPACKAGING

Ecolution Pizza Slice Crisper Pan

Ecolution Pizza Slice Crisper PanMANUFACTURING

- Bathtub Lever CoverJanuary 17, 2021

Bathtub Lever Cover

Bathtub Lever CoverInvention

Ecolution Micro-Pop – Good Design Award Winner!

Ecolution Micro-Pop – Good Design Award Winner!INDUSTRIAL DESIGN

Eco Vessel – Pint Glass Silicone Sleeve

Eco Vessel – Pint Glass Silicone SleeveMANUFACTURING

Mermaid Float by FUNBOY

Mermaid Float by FUNBOYMANUFACTURING

Skip*Hop’s Zootensils Spork

Skip*Hop’s Zootensils Spork3D MODELING

Eco Products Concept Packaging

Eco Products Concept PackagingPACKAGING

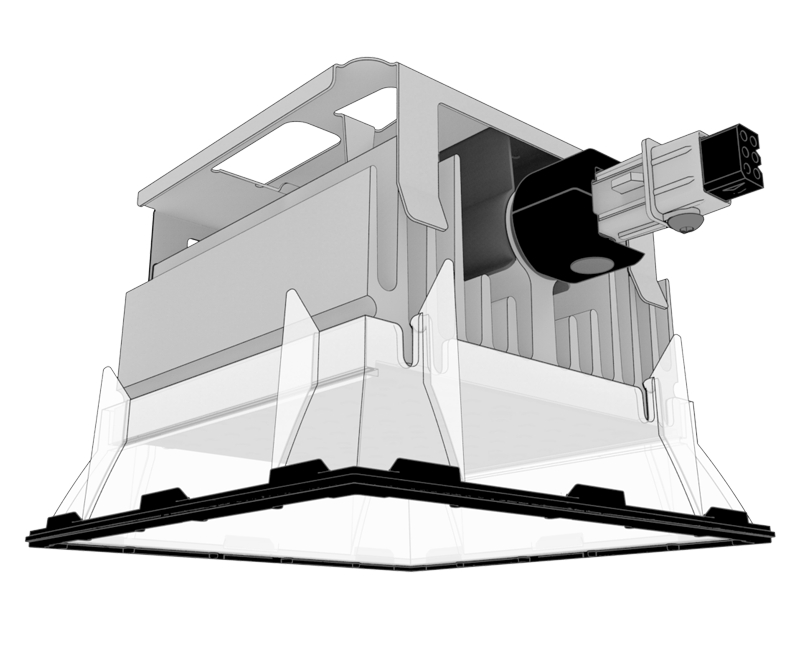

Media Display Kiosk For Triminator

Media Display Kiosk For TriminatorPOINT OF PURCHASE

Canvas Technology – Autonomous Transport

Canvas Technology – Autonomous TransportCONCEPT DEVELOPMENT

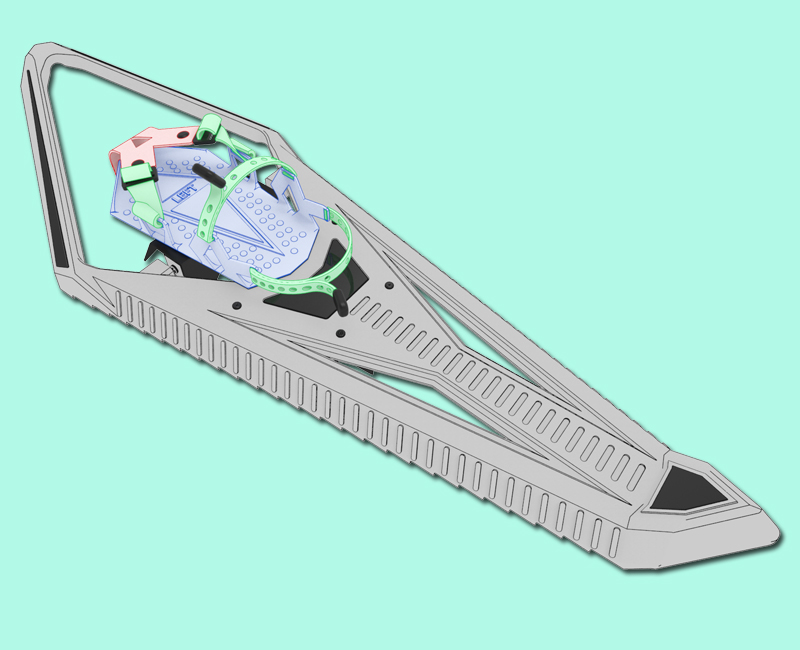

Arthur & Melody Sports Snowshoe Design

Arthur & Melody Sports Snowshoe DesignCONCEPT DEVELOPMENT

Crescent Moon Snowshoe Binding Design

Crescent Moon Snowshoe Binding DesignINJECTION MOLDING

Go Box Kiosk Display

Go Box Kiosk DisplayPOINT OF PURCHASE DISPLAY DESIGN

- WD-40 Technical DrawingFebruary 2, 2021

WD-40 Technical Drawing

WD-40 Technical DrawingTechnical Illustration

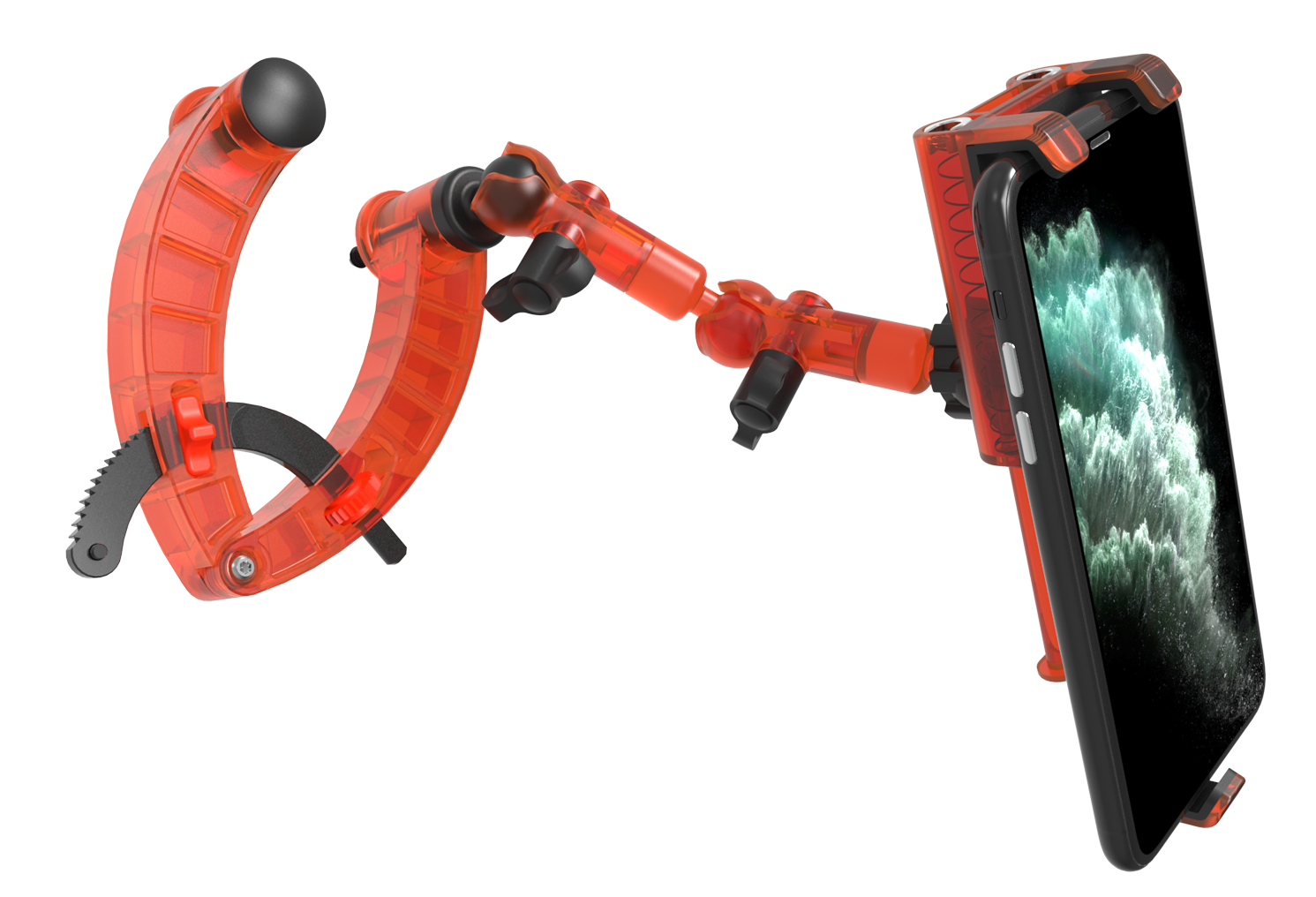

- Product Placement RenderingFebruary 14, 2021

Product Placement Rendering

Product Placement RenderingOnline Product Placement

Lets Work Together

- Hire an experienced design engineer with their design work actually made and in stores

- Easy communication by email, phone or video call

- Get the kind of focused attention you want on your project

- Customized design goals from just starting out to fine tuning an existing project

- Work with someone familiar with what it takes to invent a new product

One of the many challenges for inventors is know where to start. There are so many roads you can take and many of them can be quite pricey. By working with me you’ll be able to customize your needs while getting guidance I can offer for you as you move forward. I put together a short, helpful guide for inventors which I hope can offer a little assistance. Whether you starting from a napkin sketch or working on your next prototype please contact me with your specific project needs and we can discuss your options.

I typically charge by the project so the more inforamtion I have from you upfront the better I can assist you in determining what design process you need and provide a quote. I put together a helpful guide on the design process. Since every project is different this is just a baseline but it should give a little insight into how a lot of design projects evolve. Please email me at kylecunniff@gmail.com to start a conversation and use the download link below if you need an NDA.

About Kyle Cunniff

Kyle Cunniff is an award winning industrial designer with a strong mechanical aptitude and a well rounded skill set with over 10 years experience. He has a BID from Pratt Institute in Brooklyn, NY.

Kyle Cunniff has worked on a variety of successful products ranging from consumer goods, plastic injection molding, toys, concept visualizations, patent drawings, sell sheets and marketing products.

Market insights, concept ideation and aesthetic development coupled with a broad understanding of mechanical engineering, production & manufacturing processes, materials, and immense experience working closely with manufacturers abroad.

Kyle Cunniff’s design aesthetic focuses on sculptural, beautiful forms. This translation to consumer product design means his work has a long lasting impact in the market. That combined with a mechanical mindset allows him to focus not just on looks but functionality as well.

Pricing / Process

Click Tabs For More Info

I CHARGE BY THE PROJECT

Each project is unique and customizable to your specific needs.I typically charge by the project. When you get in touch please provide as much detail about your project as possible, including any relevant research, images, sketches and a description. If you need me to sign an NDA please download one from this site or use your own. You can email this to me filled out and I can sign and return it so you can share information with protection..

Full List of Services

If your looking for anything not on this list please get in touch.– Product design and development services (Industrial Design).

– Digital 3D CAD Models provided with detailed 2D drawing documents.

– Concept Rendering Pages + Animations (360 viewing of your product for website, presentations and marketing).

– Wide range of file types for manufacturing communication in the US and Overseas (STEP, IGES, STL, DXF, DWG) and of course Solidworks Part and Assembly files (Native)

– 3D Printing Services (vendor based, not in house)

– Reverse Engineering

– Design for Machined Plastics, Injection Molding, Metals, Plastics ABS, Polyethylene (HDPE/LEPE, Polycarbonate (PC), polyamide (Nylon), High Impact Polystyrene (HIPS), Polypropylene / Rubber Molding, TPE (Thermoplastic Elastomer) Overmolding

– Photo Realistic Renderings to use for sales brochures, printed ads, marketing images, website, portfolio, sell sheets or to help visualize the final concept.

Product Design Development Process

To give you an idea of what to expect from a project, below is a quick overview design process. Since every project is unique, the approach may differ based on your needs.1. Project Scope

When you get in touch its important I know as specifically as possible what you are looking for. Is the project more about form factor, looking at a large number of concepts? Or is it more specific and function driven? What’s on the market you like and don’t like? What samples can we find to help us understand some of the obstacles we may encounter? These are all things we’ll try to identify prior to starting the project and they will help us define the scope and direction we take. This process will also be used the quote the project.

2. Creating Concepts:

Creating a round of concept pages is the first step once I have time to research and brain storm. Concept pages help us further define a direction and can vary from very rough to more streamlined ideas. We’ll take a look at the 1st round of concepts and examine what we like an don’t like about them. Once we have enough time to review we’ll take the positive points about the first round and develop a new concept based on what we liked. Then we review. This process can take awhile before we hit the mark depending on the project. Look on my portfolio for a typical concept page.

3. 3D Design and Modeling:

During the concept development phase the 3d modeling is kept pretty loose. Once we have a direction we like we’ll fine tune the digital 3d model. We might streamline the look or make a tweak here or there.

4. 3D Model Revisions:

Another review of the 3d model is made. We take tiny steps in order to avoid any unneeded back tracking. Any necessary changes to the digital 3D model will be addressed (i.e. features, criteria, functionality, aesthetics).

5. Finalizing the project:

Upon your approval of the digital 3D modeling, 2d tech engineering drawings will be created. These aid you and the factory when talking about the design and act as a point of reference along with the final concept page and other materials compiled in a packet known as product manufacturing information (PMI). Based on your specific project needs, I can create a custom package giving you the proper documentation for your product or invention. Options include photo realistic renderings, animations, and part/assembly 2d engineering drawings.

Assistance with prototyping or fabrication can be arranged by exploring the various prototyping options and determine which is best for your product type and results you want to achieve.

Primary Services

Understanding who customers are, their desires, and their purchasing behavior is vital when designing a commercially successful consumer product.

Innovation & Strategy. The two key components to inventing, licensing and selling your idea. A good design is the best place to start. Let me guide you.

Keeping in mind production and manufacturing techniques are key to a products success. I have a strong mechanical aptitude for more engineering orientated projects.

I'm ready, how do I get in touch?

Before we talk through your project please fill out an NDA and email it to me. I will sign and return it to you. Feel free to use your own.

Once that’s done we can more easily discuss your project needs. Most often its best to email me something before a phone call so I can review and let you know if its a good fit. That way on our call I am better equipped to offer assistance and go over a potential design process.

At the very least please include a brief project explanation (ex. its a new kind of water bottle).

Generally, the list below is often what most projects will include:

- An initial "rough" design to get the ball rolling and allow us to have something to discuss more easily

- Once a direction is established, the design is stream lined for review in the form of 2d and 3d drawings/renderings

- This phase focuses on reviewing what the design looks like in detail to avoid any re-do's down the road.

- Depending on the type of project, streamlining can take just a few tweaks to several to finalize the design for prototyping/sourcing/manufacturing/production

- Finalized designs are given in a PMI packet (product manufacturing information). This gives you the tools you need to take your project to the next step whether thats marketing, crowd sourcing, 3d printing/prototyping or approaching a manufacturer for cost estimates

Inventor Information

Click Tabs For More Info

The Sell Sheet

A shorter and often less expensive approach.If you cannot convey your ideas in an impactful way, you are dead in the water. When it comes to product licensing, sell sheets are the answer. A good sell sheet makes the person who views it think, “Wow! That’s interesting. I’d like to learn more.”

A sell sheet is usually a single page layout that shows your product idea photo realistically rendered, its special features, its scale and how its used. It presents all the information about your product like selling points, features and benefits and why it stands out. This is a much lower cost approach than trying to manufacture your idea and going through the entire design development process all by yourself. The Sell Sheet is especially important when trying to license your product. By having one a buyer can quickly and easily understand what your product is and why its special.

Taking your idea all the way yourself

What you need to know to cash in on your inspiration.This can be a great route for those inventors who typically have more of a background with producing products and may even have an “in” already with potential buyers or manufacturers. Development for this route generally follows the design process listed below.

Developing your product invention yourself also makes sense if you want to make sure you have all your ducks in a row before talking to buyers so that when you do shake on the deal everything is all ready to go an your not hit with delays. It also means you have more control of the look, function and product direction than just handing off the idea and finding out later its not what you were hoping for.

Going through the design development process yourself means that you have your idea fleshed out. You may have a working or visual prototypes ready. You have a tech pack (Can show construction, colors, logo placement, dimensions, manufacturing notes, etc) showing how your idea is put together for the factory to work from. You have your PMI packet (product manufacturing information) ready to send to a factory for a quote for production or you already have the quote.

Manufacturing

The creation and assembly of components and finished products for sale on a large scale.Bare in mind any project will have to go through the factory engineers prior to production to ensure the product will be manufactured successfully. This could be checking mold threading for a water bottle to make sure it won’t leak, looking over snaps and enclosures so that they close tightly, or testing a spring latch and making sure its secure and not flimsy. These are all important measures standard to any product development and should not be overlooked, they should be expected. Prototypes help iron out design kinks and are part of the process but the factory is responsible overall for the fit, function and overall success of the product when it comes time to be manufactured.

Patents

A patent protects an invention from being stolen.Most inventors are looking for a utility patent (more protection, more expensive) or a design patent (cheaper, less protection, just prevents someone directly copying the appearance).

Once your product is designed, typically even from a sell sheet, you can begin the process of talking to a patent attorney about patenting your idea. You don’t have to have your product made or totally developed to patent it.

A U.S. patent provides the right to stop others from making, marketing, selling, or importing your invention in the United States.

Promote your design with eye catching renderings

Working with the best software out there is key to getting the results you need. Once your digital 3d modeling is complete the next phase is adding materials, lighting, texture, and environments to bring your idea to life. Use these renderings for promotions, marketing, crowd funding, technical diagrams, factory assistance and more.

Lets create beautiful animations that highlight your product features

Once your digital 3d model is finished being created in CAD the design can now be rendered. This means adding materials, finishes, textures, lighting etc to bring your product idea to life. Use animations to highlight special features and moving parts or still renderings for marketing materials, crowd funding, or a campaign to sell your product.

How can I help?

kylecunniff@gmail.com

The best way to first get in touch is by email. By letting me know even something extremely basic about your project (its a new kind of coffee maker) I can usually let you know if its something I can help you with or not. From there, we can sign and NDA, I can look over some information you provide and then we can set up a time to chat about the project.